Types of Molding

Fasten-Co outsource plastic components made from blow molding, injection molding and compression molding operations for customers seeking high-quality parts at a competitive price. Our team coordinates the supply of parts and manages the tooling and sample development, production, quality control, shipping, and inventory of the components from start to finish.

Blow Molding

Blow molding is a manufacturing process used to produce hollow plastic parts and containers. It is widely used in industries to create a variety of products, including bottles, containers, and automotive parts. The process involves inflating a heated plastic tube until it conforms to the shape of a mold.

Injection Molding

Injection Molding is a widely used manufacturing process for producing plastic parts by injecting molten plastic material into a mold. It is highly efficient for mass production of identical components with complex geometries and high precision.

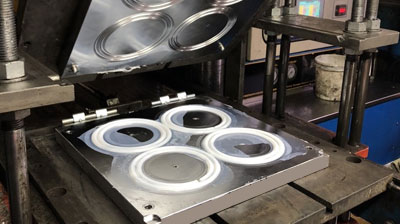

Compression Molding

Compression molding is a manufacturing process used to shape thermoset plastics and composites. It involves placing a preheated polymer material into an open, heated mold cavity. The mold is then closed, and pressure is applied to force the material into contact with all mold areas, resulting in the desired shape.